How To fasten rubberwood desktop to electric motorized steel base, in easy detach/ knock-down way using Fasteners? e.g. Wood inserts?

I'm designing & putting together a workstation desk with the following traits:

- Electric motorized (lift capacity: 120 kg) & heavy Steel frame base (30kg)

- Its a knock-down design put together using hex key-driven M6 M8 & few M10 bolts

- Rubberwood desk/ tabletop

So for consistency with the above & need for easy disassembly, I'd prefer to use similar metric bolts.

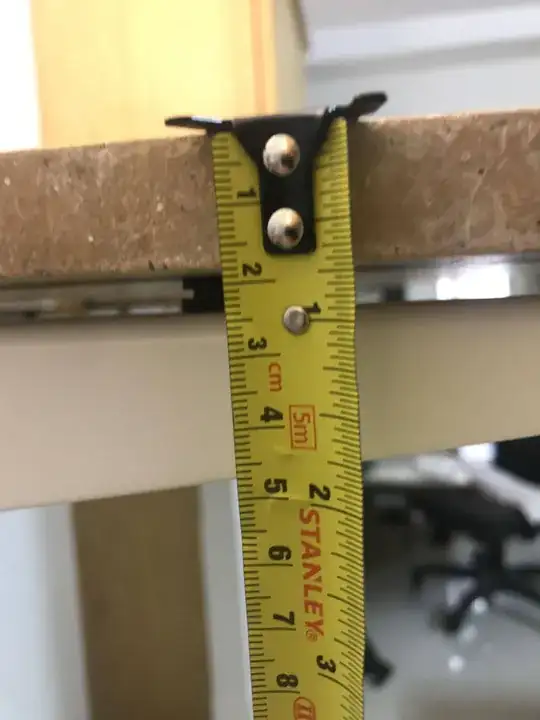

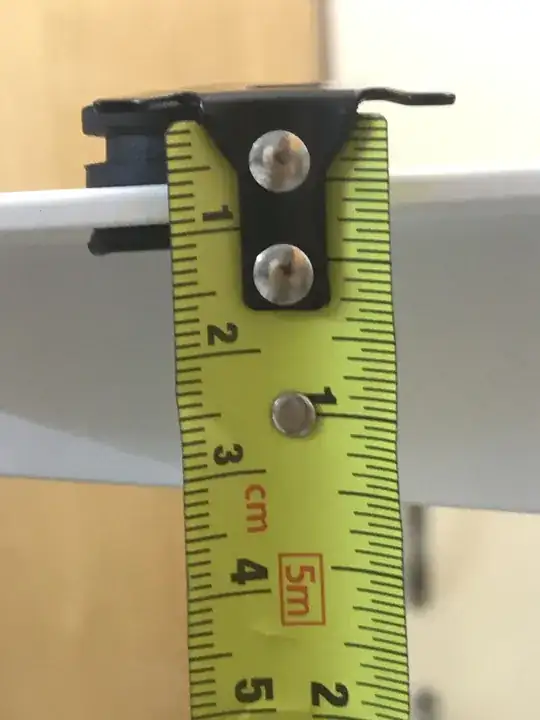

Hence, I'm considering attaching the top with metric bolts from the bottom, through the pass through layers of a steel base and a rubber cushion spacer + washer (Total: ~11mm), into matching threaded inserts.

Upon reading online the insert types I found are these and am told that top left thread-in types for hardwood would be suitable.

Commenters/ responders here have posted there are special types of other better Fasteners. I'd like to know, review them for additional "holding power" and related benefits they bring.

The rubberwood top is 18mm thick & pass through non-wood layers (~11mm). I do not know the final dimensions of the top, but assume a rectangle roughly 1m wide and under 2m long. [The OP is free to update these dimensions as necessary --jdv]

(OP: Size subject to change but within above & hence need insert for detachability)

My main questions are about the fasteners/ inserts.

- What is the safe maximum depth the inserts can be made into the rubberwood? Will this material hold inserts at all?

- Which insert style is recommended in this application?

- What special type of fasteners supersede wood inserts I've mentioned so far?

Follow-on question: Does the size of the bolt (M6, M8, M10, etc.) and matching insert matter for this application?

Update Follow-up to this Question:

Noticed a lot of variety of combinations even in threaded inserts of the hardwood type: Self tapping (advise by jdv), Slotted, 3 holes/ blind holes, collar, Hex, Reservoir, etc. (Pic from some German site)

(Image is big so linked, but can be inserted if SE folks ok - Or should these slot/ holes/ etc meta parameters go to a new Q?)

What pros cons of these in my scenario and what's recommended or to avoid? Why bother asking all this?

Scouted a dozen mom & pop hardware shops I went to did not have any.(Nothing like Home Depot).

I do see some of the above variety on local business yellow pages listing site, so they do exist & have to be found, but they don't respond to me/ consumers.

I'll eventually run into and find some variants, just not sure which ones - hence, I need to know the "yes, okay, maybe, avoid, no way" of some of the common types.