I got myself a worktop jig like this one:

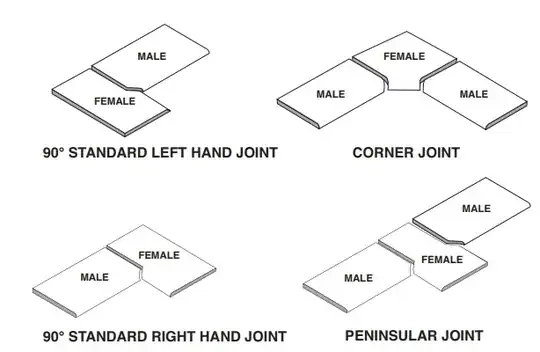

It is normally used to make 90 degrees joint for kitchen worktops, with what is called "hockey stick" cut:

The jig instructions call for a 30 mm template bushing, and a 12.7 mm x 50 mm, or 1/2" x 2", router straight bit.

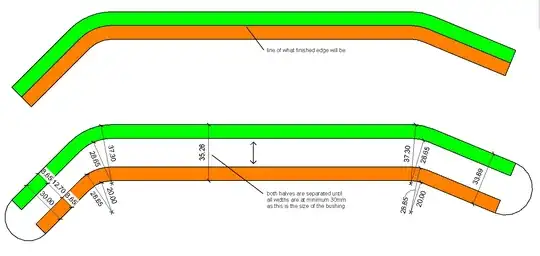

Now, I understand that the 30 mm template bushing will keep the bit center along the center of the groove - what I fail to understand is why should a 12.7 mm bit work, while any other bit doesn't work.

For what I understand, when I use this jig to make cuts, when doing the "female" cut you will be discarding what is "south" of the groove, in the picture above; when doing the "male" cut you will be discarding what is "north" of the groove.

The two edges will then necessarily have two different radii where the groove bends, so just like you cannot fit the two edges of the jig groove together, you will never be able to fit the two edges of your joint together; unless you have a 0 mm diameter bit, of course.

Now, my understanding is clearly flawed since lots of people use a jig just like the above everyday. What is it that makes this 12.7 mm so special for this jig? How is it possible that the two edges will fit together, since they are offset in opposite direction with respect to the groove center?