I'm planning on making a smallish off-road rover (15-25kg net weight) with 4-wheel steering and I was wondering if it'd be a good idea to use (self-locking) worm gearboxes for steering. I've thought about using planetary gearboxes, but self-locking gearboxes will help improve power consumption.

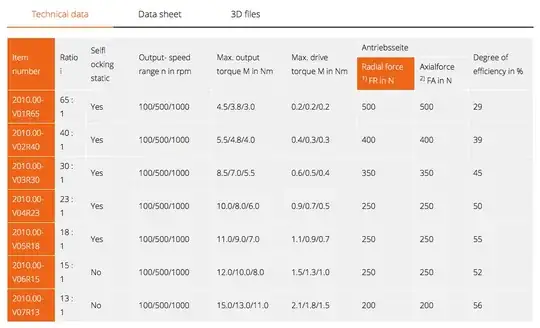

I've found this gearbox but it's not clear whether it's applicable to steering tasks. Here's the spec:

I have several questions and it'd be great if anyone could help:

As the 1:18 variant has a axial force of 250N, does that mean if the load is ~25kg, I'd need to have additional bearings and support for distributing the load?

The duty cycle is 20% at 5min. Is this generally adequate for steering? When steering in a straight line on off-road at low speed, the adjustment may be small but frequent.

A gearbox like that costs around $180. Are there more economical alternatives that are self-locking?

Any advice appreciated. TIA.