Addressing the shoulder joint, which is rather more complicated than elbows and knees... After this one, the other joints become far simpler to visualize or engineer.

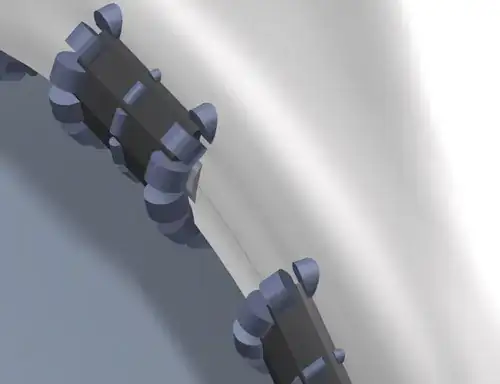

Here is how the ball and socket shoulder joint could work:

- Freedom of movement: Approximately 60 degrees end to end, all around. Less than for humans, but it can be tweaked to around 80 degrees without difficulty just by making the half-torus narrower.

- The static half-torus (shown in shiny steel here) is for strength, and would be joined to the torso exoskeleton by a rigid set of struts. Half torus = torus with an inner coaxial cylinder excised, tentative diameter of cylindrical hole 145 mm.

- The inner blued-steel hollow sphere is where the arm goes through, just beyond the actual shoulder. Tentative diameter of sphere 138mm, diameter of inner cylindrical hole 100 mm.

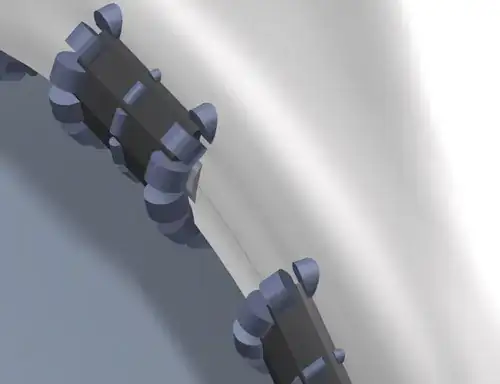

- Rings of little stepper motors on both front and hidden edges of half-torus, gripping inner hollow sphere.

- Stepper motors have outer ring rotor, inner stator, and rubberized omniwheel "teeth" to move the inner sphere.

- Inner sphere will of course be attached to a rigid exoskeleton matching the upper arm dimensions, up to the elbow joint.

This is how the motors act upon the inner sphere, close up:

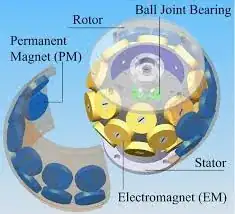

This is how each omniwheel stepper motor will work:

The omniwheel design is required for the teeth to allow frictionless motion axial to the rotation direction.