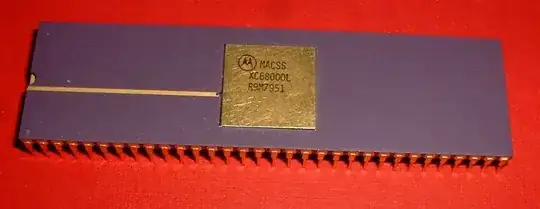

A lot of older (ceramic) ICs have a gold-plated line extending from the die cover to the edge of the package. Did this serve a practical purpose or was it just bling?

I suspect that it might be what's left of the lead frame leading to the pad under the soldered die cover. It would hold the pad in position while the package was molded. Similarly, the gold plating on the pin-1 notch in the photo below is part of the trimmed lead frame. This is just a hypothesis; can anyone confirm?