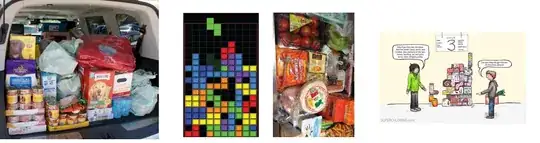

A situation that we are all familiar with : How do you decide which order to place groceries in your car or which order to place food in your fridge?

At first glance, it appears that the "order" in which you place items might be important. For instance, if you first place a small item and then place a large item on top of the small item, it will likely be a very awkward fit and result in the smaller item being damaged (e.g. a bag of flour on top of a carton of eggs). Thus, it would seemingly make more sense to first place the bigger object and then place the smaller object on top of the bigger object. Especially for many grocery items, it would appear that some orderings might be more optimal compared to other orderings.

Using this framework, can we interpret the order in which you place groceries into your car or food item into a fridge as an optimization problem? I am not sure, but this looks like some type of combinatorial optimization problem that shares aspects with the "Knapsack Optimization Problem", "Optimal Transport Optimization Problem" and "Traveling Salesman Problem" (e.g. which ordering would require lesser steps in terms of reordering items).