I have previously asked this problem here-Lead time longer than cycle time, but I keep getting more confused the more I think about it. Using the Q,R inventory model, suppose my mean monthly demand $\mu = 4000, \sigma_D = 1500$, Order quantity $Q = 6000$ and lead time $L = 3$(months). Choosing $\alpha = 2.33$, I get $SS \approx 6000$ and $ROP \approx 18000$. ROP is interpreted as the inventory position here. The values seem reasonable enough.

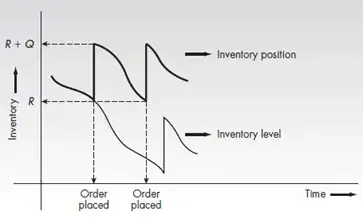

Now suppose I take $L = 10$, the safety stock value shoots up to $SS = 11,000$ and $ROP = 51,000$ This definitely seems absurdly high to me. I don't get why we use the lead time as it is in the formula because at a steady-state, and assuming the demands are normally distributed, we will be receiving an order every $Q/\mu = 6000/4000 = 1.5$ months on an average. Why, then, does the formula say that we need to use the lead time L = 10, when we know that the inventory would be replenished much before that? In my opinion, we only need to cover-up for fluctuations in demand in that 1.5 month period. I couldn't find any text that clearly explains this dichotomy between Inventory Position and Inventory Level and any help is appreciated.