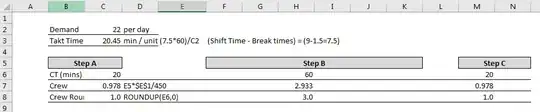

I have a 3 step process. Step A takes 20 min, Step B : 60 min, Step C : 20 min

Steps in production of output "news nuggets" is as below:

Step A : Do Secondary Research

Step B : Analyse the data, Generate Insights, Arrange Information

Step C : Check Grammar, Formatting & convert to PDF

My Questions:

- Is my calculation of crew size correct ?

- What step is the constraint and why?

- Manual calculation as in the excel (attached) makes Step C as constraint.

- What is the best way to allocate resources.PS: The flow is assumed to be constant